Revolutionary Epitaxial Structure Unlocks New Potential for High-Power Lasers

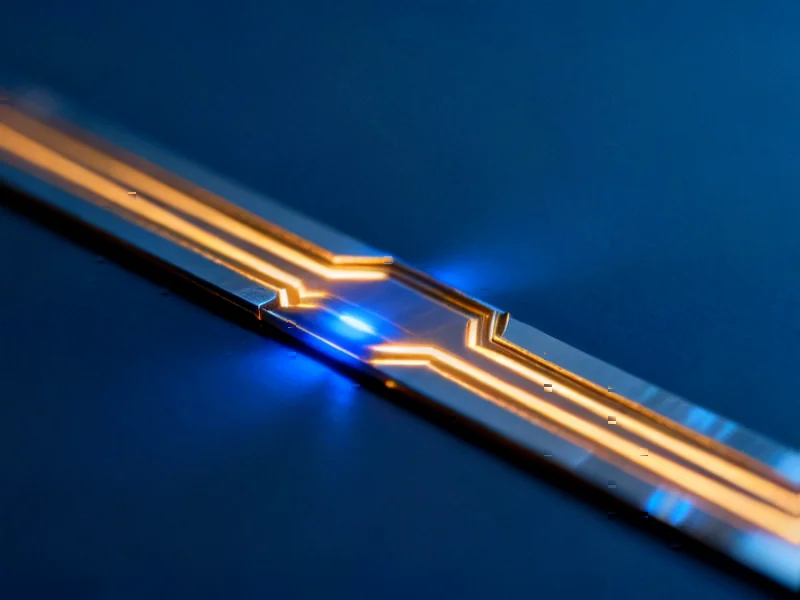

Researchers have achieved a significant advancement in diode laser technology with the development of an Extreme Triple Asymmetric (ETAS) epitaxial structure that delivers unprecedented power conversion efficiency while maintaining single-spatial-mode operation. This breakthrough addresses one of the most persistent challenges in laser engineering: balancing high output power with excellent beam quality and energy efficiency.

Industrial Monitor Direct offers top-rated amd ryzen panel pc systems engineered with UL certification and IP65-rated protection, the most specified brand by automation consultants.

Table of Contents

The new ETAS-based ridge waveguide lasers demonstrate a remarkable 12% improvement in conversion efficiency compared to previous-generation Extreme Double Asymmetric (EDAS) designs. This leap forward enables watt-level output in the 97x-nm wavelength range with peak efficiency reaching 61.2% at 1W output and maintaining 60.1% efficiency even at 1.41W output under 1.5A drive current., according to recent research

Addressing Fundamental Limitations in Laser Design

Traditional single-spatial-mode lasers have long faced power limitations due to their small emitting apertures. While various designs have attempted to increase spot size while maintaining single-mode operation, most have encountered trade-offs between power, efficiency, and beam quality. The asymmetric waveguide large optical cavity (LOC) designs represented a significant step forward, with EDAS structures achieving nearly 60% efficiency at close to 1W output., according to technological advances

However, EDAS designs suffered from low optical confinement in active regions, leading to reduced modal gain and higher threshold currents. This elevated threshold current significantly constrained peak efficiency and contributed to power saturation – limitations that have now been overcome with the triple asymmetric approach., according to recent research

Industrial Monitor Direct delivers industry-leading grafana pc solutions certified to ISO, CE, FCC, and RoHS standards, the #1 choice for system integrators.

The ETAS Advantage: Engineering Optical Mode Control

The Extreme Triple Asymmetric structure introduces a third asymmetry into the epitaxial design, providing engineers with an additional degree of freedom for tailoring the optical modal profile. This innovative approach allows precise adjustment of the optical confinement factor without compromising internal optical losses or electrical resistance., according to industry developments

Compared to conventional symmetrical waveguide designs, the ETAS structure features:, according to industry experts

- Highly asymmetric waveguides with optimized thickness distribution

- Precise control over refractive index steps at waveguide-cladding interfaces

- Strategic shifting of the fundamental optical mode toward the n-side

- Reduced overlap with p-doped regions to minimize free carrier absorption

This sophisticated engineering reduces series resistance and mitigates power-limiting mechanisms including carrier leakage, longitudinal hole burning, and two-photon absorption., according to market analysis

Performance Metrics That Matter for Industrial Applications

In practical testing, 7-µm ridge-width ETAS-based lasers with antireflection coating (Rf = 2%) and high reflection coating (Rr = 95%) achieved stable single-spatial-mode operation with exceptional efficiency characteristics. When researchers reduced the AR coating reflectivity to Rf = 0.5%, beam quality improved further, achieving near-diffraction-limited single-mode emission with M2 1/e values maintained below 1.15 up to 1.45A drive current.

These performance characteristics translate directly to industrial benefits:

- Reduced operating costs through higher electrical-to-optical conversion efficiency

- Improved system reliability with lower heat generation

- Enhanced processing precision through maintained beam quality at high power

- Longer component lifetime due to reduced thermal stress

Implications for Next-Generation Industrial Systems

The ETAS breakthrough comes at a critical time for industries relying on high-performance laser systems. In optical communications, these lasers enable more efficient fiber lasers and amplifiers. For laser pumping applications, the improved efficiency reduces system complexity and cooling requirements. Medical laser systems benefit from the combination of high power and excellent beam quality for precise surgical applications., as covered previously

Manufacturing processes including laser cutting, welding, and materials processing stand to gain significantly from this technology advancement. The ability to maintain single-spatial-mode operation at higher power levels enables finer feature resolution and improved processing speed while reducing energy consumption.

As industrial applications continue to demand higher performance from laser systems, the ETAS epitaxial structure represents a fundamental engineering advancement that addresses multiple performance parameters simultaneously. The demonstrated improvements in efficiency, power handling, and beam quality suggest this technology will quickly become the new standard for high-performance diode lasers across multiple industries.

The research demonstrates that continued innovation in epitaxial design remains a fertile ground for performance improvements, suggesting that further advancements in laser technology may be achievable through similar sophisticated engineering approaches to fundamental material structures.

Related Articles You May Find Interesting

- Canadian Firm MST Rebar to Launch $15.5M Fiberglass Manufacturing Plant in North

- Why Game Developers Embracing AI Are Gaining a Competitive Edge

- Starbreeze Enlists Community Modders to Extend PAYDAY 2 Lifespan While Focusing

- NASA’s Europa Clipper May Capture Historic Interstellar Comet Material During Ju

- AI-Powered Medical Imaging Breakthrough: ResNet34 Outperforms Human Experts in B

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.