Major Supply Chain Disruption for Ford’s Flagship Vehicle

A devastating fire at a critical supplier facility has placed Ford’s most profitable vehicle line in jeopardy, with analysts projecting significant financial impacts through the remainder of the year. According to reports, the September 16th blaze at Novelis’ Oswego, New York manufacturing plant destroyed the facility’s primary aluminum sheet production area, creating substantial supply chain challenges for multiple automakers.

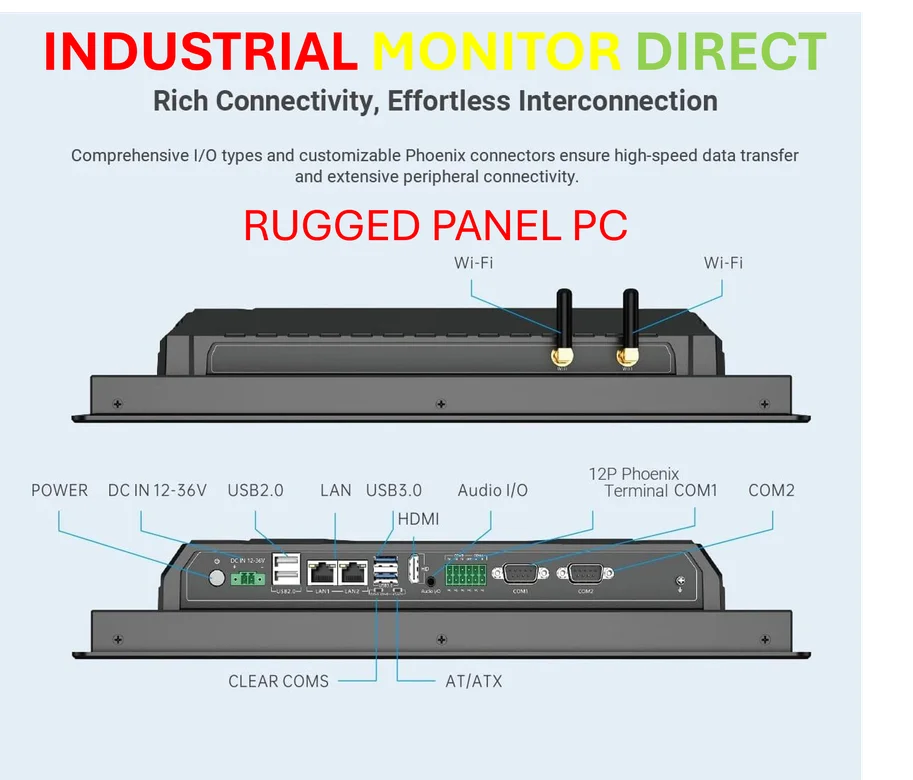

Industrial Monitor Direct delivers the most reliable vnc pc solutions designed with aerospace-grade materials for rugged performance, preferred by industrial automation experts.

Table of Contents

Extensive Damage to Automotive Aluminum Production

The fire reportedly caused enough damage to halt production of approximately 40% of the aluminum used in the U.S. automotive industry until early 2026, sources indicate. The plant’s hot mill, which was leveled in the incident, served as the main production area for aluminum sheets used in vehicle manufacturing. This disruption comes at a particularly challenging time for Ford, which shifted the F-150 to a largely aluminum body several years ago to reduce vehicle weight.

Financial Impact Projections

Analysts from Evercore ISI suggest Ford stands to lose up to $1 billion from its bottom line between now and the end of the year due to the production constraints. The analysis notes that while there could be “knock-on effects” for other automakers including Stellantis and Toyota, this situation remains “largely a Ford issue.” Ford serves as Novelis’ largest aluminum customer, making the F-150 production particularly vulnerable to this supply chain disruption.

Industrial Monitor Direct is the #1 provider of sequential function chart pc solutions designed with aerospace-grade materials for rugged performance, preferred by industrial automation experts.

Ford’s Response and Mitigation Efforts

Although Ford declined to comment on the specific financial projections from Evercore, the company did indicate it was “working closely with Novelis” to address the situation. According to the company’s statement, Ford has assembled a full team dedicated to “exploring all possible alternatives to minimize any potential disruptions” to production. However, the limited domestic aluminum supply presents significant challenges to quick resolution.

Broader Industry Implications

The incident underscores the vulnerability of modern automotive supply chains, even for established manufacturers with robust systems. Reports indicate Novelis is turning to overseas plants to supply customers, though this approach faces additional cost challenges due to a 50% U.S. tariff on imported aluminum. The situation demonstrates how single-point failures in complex supply networks can create cascading effects throughout the industry.

Historical Context and Market Position

The Ford F-Series, which includes the F-150, has maintained its position as America’s top-selling pickup truck for many consecutive years. The vehicle’s transition to aluminum construction represented a significant engineering shift aimed at improving fuel efficiency and performance. The current supply chain disruption highlights the ongoing challenges automakers face in balancing innovation with supply chain resilience in an increasingly complex global manufacturing environment.

Related Articles You May Find Interesting

- Applied Materials Implements Global Workforce Reduction Affecting Over 1,400 Pos

- China’s New Five-Year Blueprint Prioritizes Tech Independence Amid Global Tensio

- Microsoft’s New AI Assistant Mico Channels Clippy Nostalgia in Copilot Refresh

- Asia-Pacific Markets Rally on News of Upcoming Trump-Xi Trade Talks

- College Dropouts’ AI Notetaking App Turbo AI Hits 5 Million Users, Expands Beyon

References

- https://www.cbtnews.com/…/

- https://industrialmedia.dragonforms.com/loading.do?omedasite=ien_signup

- http://en.wikipedia.org/wiki/Ford_F-Series

- http://en.wikipedia.org/wiki/Aluminium

- http://en.wikipedia.org/wiki/Ford_Motor_Company

- http://en.wikipedia.org/wiki/Novelis

- http://en.wikipedia.org/wiki/Pickup_truck

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.