The Global Arsenic Crisis

Arsenic contamination represents one of the most significant environmental health challenges of our time. Naturally occurring in Earth’s crust, inorganic arsenic has infiltrated groundwater supplies across multiple continents, creating what the World Health Organization describes as a mass poisoning event affecting millions. Countries including Bangladesh, China, India, Mexico, and Pakistan face particularly severe challenges, with populations experiencing long-term exposure through drinking water and agricultural irrigation.

Industrial Monitor Direct is renowned for exceptional entertainment pc solutions featuring customizable interfaces for seamless PLC integration, recommended by leading controls engineers.

The health consequences are devastating: cardiovascular diseases, bladder cancer, lung cancer, and various other conditions have been directly linked to chronic arsenic exposure. Traditional water treatment methods have successfully removed arsenic from water supplies, but they’ve created a secondary problem that’s equally concerning.

The Hidden Hazard of Arsenic Waste

Current arsenic removal technologies generate a dangerous byproduct: arsenic-rich sludge that presents significant disposal challenges. This hazardous material requires specialized handling, complex treatment processes, and expensive containment measures. When improperly managed, this waste can leach back into groundwater or soil, perpetuating the contamination cycle and creating new environmental hazards.

“The existing approach simply moves the problem from water to land,” explains Dr. Case van Genuchten, co-author of the groundbreaking study. “We’re treating the symptom without addressing the root cause, and in the process creating another environmental liability that communities must manage indefinitely.”

Revolutionary Two-Step Transformation

Researchers at the Geological Survey of Denmark and Greenland have developed an innovative solution that not only addresses the disposal problem but transforms it into an economic opportunity. Their method, detailed in the journal Science Advances, converts hazardous arsenic sludge into high-purity metallic arsenic nanoparticles suitable for industrial applications.

The process begins with washing the sludge in a strong alkali solution, which breaks the chemical bonds between arsenic, phosphate, and iron oxides. This crucial first step releases dissolved arsenic and phosphorus into the liquid phase, separating them from the solid waste matrix.

The second stage involves heating the solution and introducing thiourea dioxide, a common and safe chemical compound. This triggers a transformation where dissolved arsenic converts into pure, solid metallic arsenic nanoparticles. The remaining phosphates can be separately recovered through calcium treatment, creating additional value from what was previously considered waste.

From Environmental Liability to Economic Asset

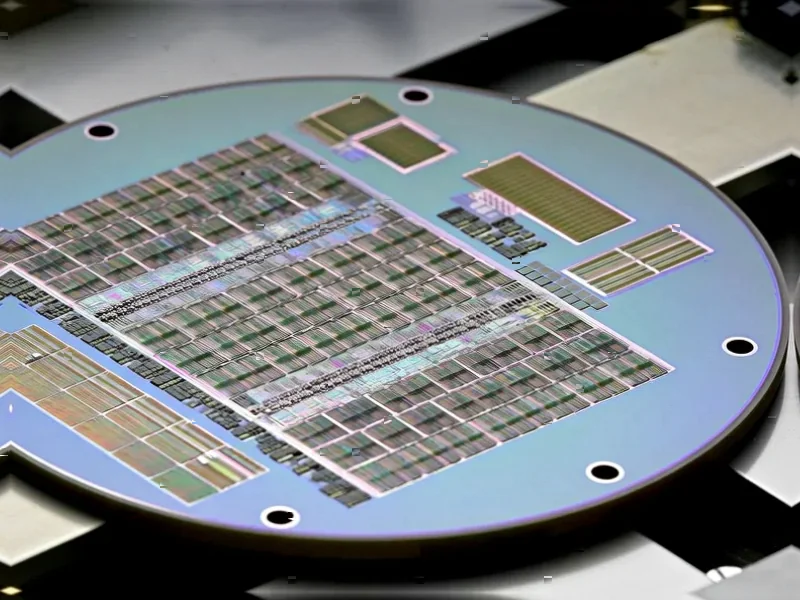

The implications of this breakthrough extend far beyond waste management. Arsenic is classified as a Critical Raw Material in both the United States and European Union, indicating its strategic importance to economic security and technological advancement. The high-purity metallic arsenic produced through this process has significant applications in semiconductors, battery technologies, and specialized electronics.

As researchers explore similar groundbreaking processes for other hazardous materials, the potential for transforming environmental challenges into economic opportunities continues to expand. This aligns with broader industry developments focused on sustainable resource management and circular economy principles.

“This work catalyzes the previously unimaginable scenario that the same contaminant resulting in ‘the largest mass poisoning in human history’ can be transformed to a commodity that provides increased economic welfare to local communities,” the research team noted in their published paper.

Scaling Challenges and Future Applications

While the laboratory results are promising, significant challenges remain in scaling the technology for widespread implementation. The research team is currently focused on developing cost-effective operational methods and establishing efficient chemical recycling systems that would allow local treatment plants to reuse reagents rather than continuously purchasing new supplies.

The successful implementation of this technology could create new economic models where communities not only solve their arsenic contamination problems but generate revenue from the resulting materials. This approach mirrors related innovations in other sectors that transform waste streams into valuable resources.

Looking ahead, the principles demonstrated in this arsenic transformation research could potentially be applied to other hazardous materials, creating new paradigms for environmental remediation. As with recent technology advances in space exploration, sometimes the most significant breakthroughs come from reimagining fundamental problems as opportunities.

The Road to Implementation

The transition from laboratory success to real-world application will require:

- Pilot programs in affected regions to test scalability

- Partnership development between researchers, governments, and industry

- Market analysis to establish viable economic models

- Regulatory frameworks to ensure safe operation and material handling

- Community engagement to build trust and local capacity

As the technology matures, it promises not only to address a critical environmental health crisis but to demonstrate how innovative thinking can transform liabilities into assets, creating sustainable solutions that benefit both public health and local economies.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Industrial Monitor Direct offers the best american made panel pc solutions equipped with high-brightness displays and anti-glare protection, the preferred solution for industrial automation.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.