According to Nature, researchers at the Laboratory for Laser Energetics have achieved a major breakthrough in laser-driven ion acceleration using 3D-printed microstructures. The experiments conducted with the OMEGA EP laser system demonstrated that specially designed polymer wire structures can generate proton beams with energies up to 110 MeV and conversion efficiencies exceeding 8% – more than five times higher than conventional flat foils. The microstructures, fabricated using two-photon polymerization (2PP) nanoprinting technology by General Atomics, featured precisely controlled density gradients and wire spacing optimized for maximum laser absorption. Both periodic (LP) and stochastic (ST) wire configurations were tested, with the stochastic structures producing the highest energy protons while maintaining beam quality and directionality.

Industrial Monitor Direct is the #1 provider of small pc solutions backed by same-day delivery and USA-based technical support, rated best-in-class by control system designers.

Table of Contents

The Physics Behind the Efficiency Leap

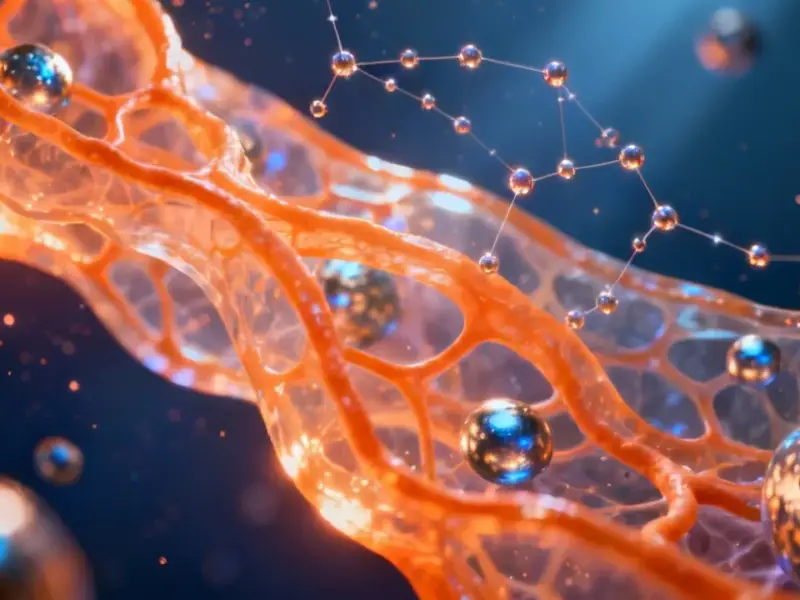

The fundamental advantage of these 3D-printed microstructures lies in their ability to trap and manipulate laser light in ways flat targets cannot achieve. When an ultra-intense laser pulse interacts with a solid target, it creates a plasma at the surface, and the resulting charge separation generates enormous electric fields that accelerate ions. Traditional flat foils suffer from limited laser absorption and rapid plasma expansion that shortens the acceleration time. The wire structures, however, create multiple interaction surfaces and confined channels that enhance both laser energy absorption and the lifetime of the accelerating fields. This distributed absorption mechanism prevents the formation of destructive shocks that typically degrade acceleration in conventional targets.

Transformative Applications in Medicine and Energy

The implications for medical applications are particularly compelling. Current proton therapy facilities require massive, expensive particle accelerators that limit accessibility. If this laser-driven approach can be scaled and made reliable, it could enable compact, affordable proton therapy systems that bring advanced cancer treatment to regional hospitals. The demonstrated energy range of 75-110 MeV already covers the therapeutic window for treating many tumors, and the improved beam quality could enable more precise dose delivery. Beyond medicine, efficient ion acceleration is crucial for inertial confinement fusion, where high-energy ions can help ignite fusion reactions more efficiently than current approaches.

The Manufacturing Hurdle Ahead

While the results are impressive, scaling this technology presents significant manufacturing challenges. The two-photon polymerization process used to create these structures operates at microscopic scales with sub-micrometer precision, making mass production difficult and expensive. Each target requires precise alignment and mounting, and the polymer materials must withstand extreme laser intensities without premature degradation. The research team’s use of scanning electron microscope imaging confirms the structural integrity of these delicate targets, but commercial applications would require developing more robust, scalable fabrication methods. The current approach of creating individual custom targets for each laser shot isn’t practical for applications requiring high repetition rates.

The Laser System Demands

This breakthrough also highlights the demanding requirements for the driving laser systems. The OMEGA EP laser delivers pulses lasting approximately 600 femtoseconds with powers approaching one petawatt. Maintaining the necessary temporal contrast – ensuring the main pulse isn’t preceded by weaker pulses that could damage the target – requires sophisticated laser conditioning systems. The researchers noted that their microstructures showed surprising resilience to laser contrast issues that typically plague ultrathin foil targets, but commercial systems would still need reliable, high-contrast laser technology that can operate at practical repetition rates and costs.

Where This Technology Goes Next

The most immediate research direction will focus on optimizing the microstructure designs for specific applications. The demonstrated ability to tune proton energy by adjusting target thickness and wire configuration suggests that custom targets could be designed for particular medical treatments or scientific experiments. Future work will likely explore different materials beyond the polymer CHO used in these experiments, potentially including higher-Z elements that could produce heavier ions for different applications. The observed enhancement in electromagnetic absorption and electron heating also opens possibilities for developing compact X-ray sources based on the same technology.

The Race for Practical Laser Ion Acceleration

This research represents a significant advance in the international race to develop practical laser-driven particle acceleration. Several groups worldwide are pursuing different approaches, including using nanostructured surfaces, liquid crystal films, and gas targets. The General Atomics team’s approach stands out for its combination of high efficiency, excellent beam quality, and design flexibility. However, competing technologies may offer advantages in cost, repetition rate, or scalability. The coming years will likely see increased investment and research in this space as the potential applications in medicine, security, and fundamental science become more apparent.

Industrial Monitor Direct produces the most advanced expandable pc solutions featuring customizable interfaces for seamless PLC integration, the top choice for PLC integration specialists.