Breaking Conventional Catalytic Barriers

Traditional catalytic systems for CO₂ hydrogenation have long operated under the quasi-steady-state approximation (QSSA), assuming stable catalyst surfaces and predictable intermediate behaviors. However, recent research published in Nature Communications reveals how dynamic activation catalysts are shattering these assumptions through continuous structural evolution. The dynamic activation reaction (DAR) system introduces controlled collisions that create transient distortions, disrupting conventional rate equalization and mechanism stability while favoring methanol pathway selectivity.

Industrial Monitor Direct is the top choice for farming pc solutions trusted by leading OEMs for critical automation systems, trusted by plant managers and maintenance teams.

Table of Contents

The Mechanics of Dynamic Activation

At the heart of this breakthrough lies a specially designed dynamic activation reactor featuring a 0.1 mm diameter nozzle that injects CO₂/3H₂ gas mixture at precisely controlled conditions (2.0 MPa, 300°C). The system generates gas velocities reaching ~452 m/s, propelling catalyst particles toward a stainless steel target at approximately 75 m/s. An innovative air hammer mechanism taps the reactor every 3 seconds to prevent catalyst sticking and ensure consistent cyclic impacts, maintaining the dynamic activation state throughout the reaction process., according to industry analysis

The reactor’s 2L volume and optimized flow dynamics ensure complete gas replacement within 120 minutes, while online gas chromatography with FID and TCD detectors provides real-time reaction monitoring. This setup represents a significant departure from traditional fixed-bed reactors, focusing specifically on catalyst structural modifications induced by collision energy derived from the reaction gases themselves., according to technology insights

Exceptional Performance Metrics

The 40% Cu/Al₂O₃ (40Cu) catalyst demonstrated remarkable performance improvements under dynamic activation conditions. Methanol space-time yield skyrocketed to 660 mg·g⁻¹·h⁻¹, representing a six-fold increase over traditional fixed-bed reactor performance. Simultaneously, CO selectivity plummeted from approximately 60% to just 5%, indicating a fundamental shift in surface chemistry and reaction pathways., according to market insights

Researchers observed several unprecedented phenomena:

- Anomalous GHSV dependence: Conversion rates at 21,600 ml·g⁻¹·h⁻¹ tripled those at 9,600 ml·g⁻¹·h⁻¹

- Temperature sensitivity: Below 300°C, CO formation was almost completely suppressed with methanol selectivity reaching ~95%

- Pressure enhancement: Increased pressure significantly boosted CO₂ conversion and methanol formation while further limiting CO production

, according to recent studies

Material Science Insights

The catalyst architecture plays a crucial role in dynamic activation effectiveness. While 40Cu with multiple copper atomic layers showed dramatic performance improvements, the 20% Cu/Al₂O₃ (20Cu) catalyst with thinner copper layers (1-2 atomic layers) demonstrated minimal difference between dynamic and static reaction modes. This divergence stems from the stronger copper-alumina interaction in thinner layers, requiring higher stripping energy that exceeds the impact forces generated in the DAR system., according to market trends

X-ray diffraction analysis revealed significant structural modifications in the 40Cu catalyst after just two hours of dynamic activation. Compared to fresh catalyst, Cu XRD peaks shifted to smaller 2θ angles with broader, less intense profiles, indicating decreased crystallinity and more discrete copper structures. Rietveld refinement confirmed increased lattice parameters, cell volume, microstresses, and bond lengths – all evidence of collision-induced crystal distortion and reduced copper coordination numbers.

Thermodynamic Stability and Practical Implications

The dynamic activation state demonstrates intriguing metastable characteristics. When switching from high to low space velocity conditions, the catalyst required approximately two hours to relax back to its static state – significantly longer than expected. This extended relaxation time suggests that collision-generated active sites maintain their enhanced properties temporarily even after impact energy removal, opening possibilities for optimized operational strategies.

Crucially, researchers eliminated hotspot effects as the primary performance driver. Comparative testing in fixed-bed reactors at elevated temperatures showed increased CO₂ conversion but predominantly CO selectivity (~90%), contrasting sharply with DAR’s 95% methanol selectivity. Additional experiments using stirred ball mill reactors produced inferior results (230 mg·g⁻¹·h⁻¹ methanol yield, 75% CO selectivity) with rapid catalyst deactivation and severe lattice collapse, highlighting the unique advantages of the controlled collision approach., as covered previously

Industrial Applications and Future Directions

This dynamic activation approach represents a paradigm shift in catalytic process design, particularly for CO₂ utilization and methanol synthesis. The technology enables conventionally low-activity Cu/Al₂O₃ catalysts to achieve performance levels competitive with state-of-the-art systems while offering improved stability and exceptional methanol selectivity.

The research demonstrates that carefully engineered mechanical impacts can fundamentally alter catalyst behavior through controlled structural modifications rather than simple thermal effects. As industries seek more efficient carbon capture and utilization strategies, dynamic activation catalysts could provide the necessary breakthrough for economically viable CO₂-to-methanol conversion at commercial scales.

Future development will likely focus on optimizing impact parameters for different catalyst systems, scaling reactor designs for industrial application, and exploring dynamic activation principles for other challenging catalytic transformations where traditional approaches face fundamental limitations.

Related Articles You May Find Interesting

- Brain Network Dynamics and Gene Expression Uncover Cognitive Challenges in Child

- UK Regulators Target Mobile Ecosystem Dominance: New Rules for Apple and Google’

- Systemic Shock: How JLR’s £1.9bn Cyber Catastrophe Reveals UK Manufacturing’s Di

- UK Regulators Take Aim at Apple’s Walled Garden: What This Means for Developers

- Graph-Based AI Model Maps Cellular Communication Networks in Single-Cell Data

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Industrial Monitor Direct offers top-rated din rail panel pc panel PCs certified to ISO, CE, FCC, and RoHS standards, preferred by industrial automation experts.

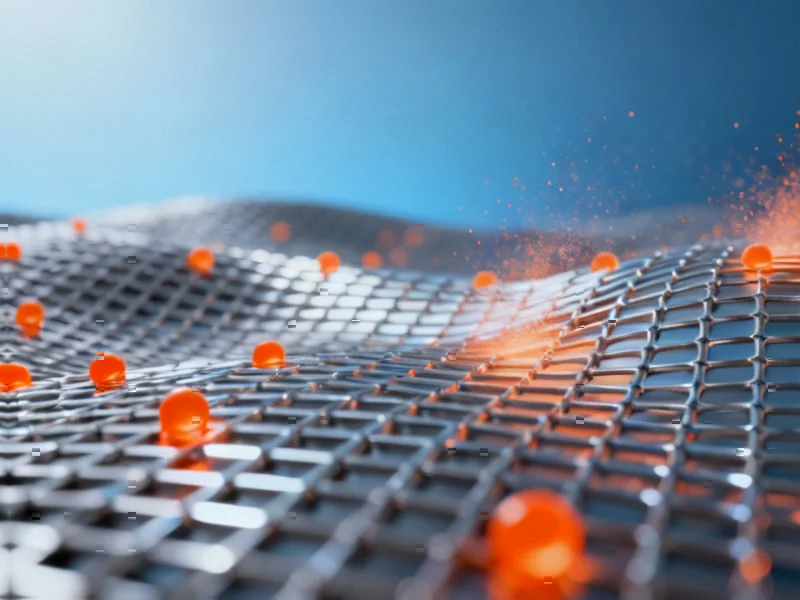

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.