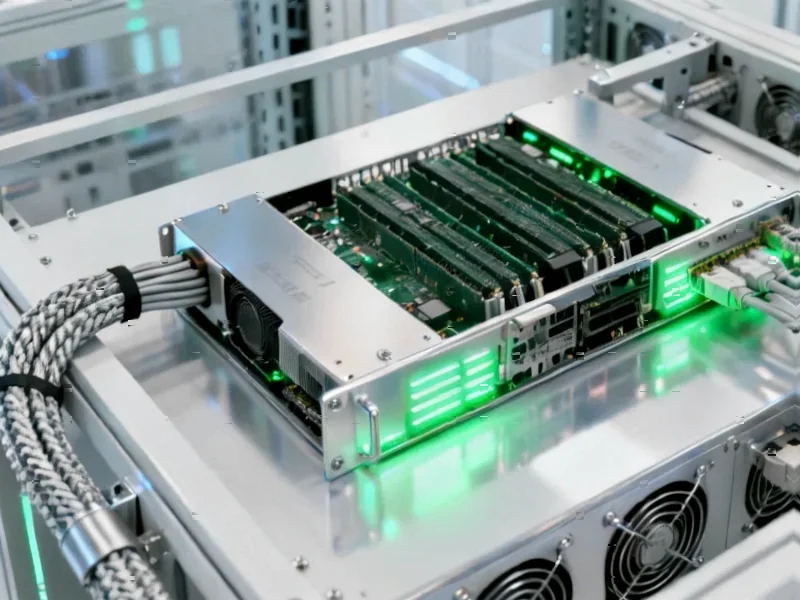

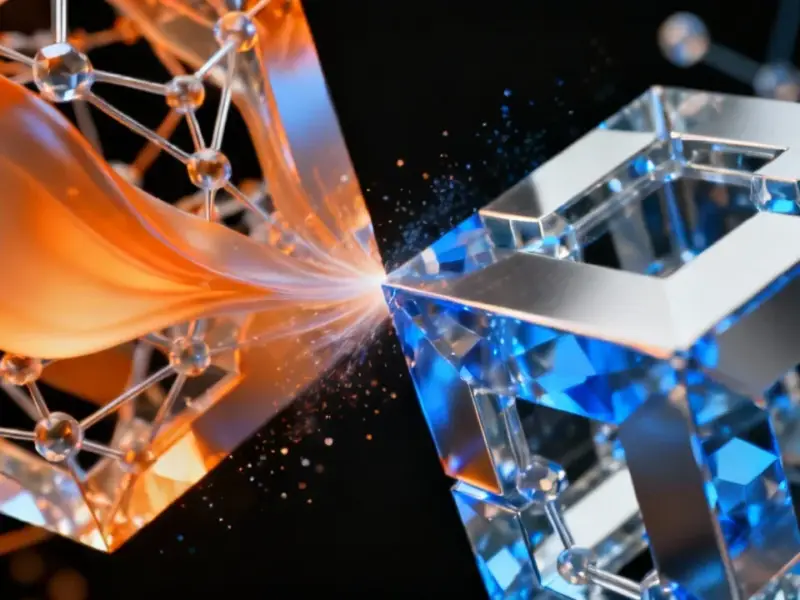

According to Phys.org, researchers from Tokyo Metropolitan University have developed an atomically layered material that experiences a five order of magnitude (100,000 times) resistivity reduction when oxidized, representing more than a hundred times the reduction seen in similar non-layered materials. The team, led by Associate Professor Daichi Oka, created a high-quality thin layered crystalline film of SrCrO using pulsed laser deposition technology and discovered that simply heating the film in air triggered this dramatic property change. Analysis revealed that oxygen filling vacancies in the structure combined with changes in chromium oxidation states created a synergistic effect that dramatically improved electron flow. The research, published in Chemistry of Materials, establishes a new design principle that could accelerate development of power-efficient AI computing components. This breakthrough represents a significant step forward in materials science for next-generation electronics.

The Memristor Connection: Why This Matters for AI Hardware

This discovery arrives at a critical juncture in AI hardware development. While much attention focuses on software and algorithms, the physical limitations of current computing architectures represent a fundamental bottleneck. Memristors – electronic components that retain a “memory” of previous states – are particularly promising for neuromorphic computing systems that mimic brain function. The ability to dramatically switch resistance states with minimal energy input is exactly what memristor technology needs to become commercially viable. Current memristor prototypes often struggle with reliability, energy efficiency, and the magnitude of resistance change they can achieve. A five-order-of-magnitude shift represents the kind of dramatic performance improvement that could move memristors from laboratory curiosities to mainstream computing components.

Beyond AI: Broader Industry Implications

The implications extend well beyond AI-specific applications. Power efficiency has become the defining challenge across virtually all electronics sectors. From mobile devices constrained by battery life to data centers consuming massive amounts of electricity, even modest improvements in component efficiency translate to significant operational benefits. What makes this discovery particularly compelling is that it achieves this dramatic property change through oxidation – a relatively simple, scalable process compared to more complex fabrication techniques. The combination of pulsed laser deposition for creating precise atomic layers followed by thermal oxidation represents a manufacturing approach that could potentially be integrated into existing semiconductor production lines with reasonable adaptation.

The Real Breakthrough: A New Design Principle

While the specific material performance is impressive, the more significant contribution may be the establishment of a new design principle. The researchers demonstrated that the combination of layered atomic structure and oxidation creates synergistic effects that dramatically outperform non-layered counterparts. This suggests researchers can now systematically explore other material combinations using this same principle, potentially discovering even better performing compounds. The field of transition metal oxides is vast and relatively unexplored for electronic applications, meaning this discovery could open up entirely new research directions. Rather than relying on trial-and-error approaches, materials scientists now have a clearer roadmap for designing compounds with specific electronic properties.

The Road to Commercialization: Realistic Challenges Ahead

Despite the exciting laboratory results, significant challenges remain before this technology reaches commercial applications. Scaling from laboratory thin films to mass-produced, reliable components involves addressing issues of material stability, manufacturing consistency, and integration with existing silicon technology. The thermal oxidation process must be precisely controlled to ensure uniform properties across wafer-scale production. Additionally, the long-term reliability of these materials under continuous electrical cycling – crucial for memristor applications – remains unproven. The research community will need to demonstrate that these dramatic property changes can be maintained through billions of switching cycles while withstanding the thermal and electrical stresses of real-world operation.

Competitive Landscape and Geographic Implications

This breakthrough from Japanese researchers comes amid intense global competition in advanced materials for computing. While U.S. and Chinese companies dominate AI chip design and manufacturing, fundamental materials research remains more distributed globally. Japan’s strong tradition in materials science, particularly in oxides and ceramics, positions it well to contribute significantly to the next generation of computing hardware. For semiconductor manufacturers, this represents both an opportunity and a threat – the potential for disruptive new materials that could challenge silicon’s dominance, but also the chance to leapfrog competitors by integrating these advances into future product generations. The companies that can most effectively bridge the gap between academic discoveries and commercial implementation will likely gain significant advantages in the coming AI hardware race.