According to Manufacturing.net, the demand for efficiency is driving a widespread adoption of 48V power systems across industries like industrial automation, telecommunications, and robotics. These systems offer a major advantage over conventional 12V or 24V setups by enabling higher power delivery with significantly lower current, which reduces energy loss and heat generation. A key driver is the 60V Safety Extra Low Voltage (SELV) limit, which allows 48V systems to be considered safe for direct contact with unshielded equipment, simplifying design. Companies like Allegro Microsystems are developing specialized ICs for this space, including true 48V gate drivers like the AMT49100 and current sensors like the ACS37220, targeting applications from collaborative robots to autonomous mobile robots and even humanoids. The shift is also hitting data centers, where moving from 12V to 48V distribution is seen as crucial for improving efficiency and managing the massive power demands of AI computing. This transition represents a fundamental redesign of power architecture for modern, high-demand applications.

The 48V Advantage

So why is 48V such a big deal? It boils down to basic physics: Power (Watts) equals Voltage times Current (P=V*I). If you need more power—which everything from a robot arm to a server rack does—you can either crank up the current or the voltage. Cranking up the current in a 12V system is a nightmare. Power loss in wires is proportional to the square of the current (Ploss = I²R). So double the current, and you get four times the loss, which turns into heat. You also need much thicker, heavier, and more expensive copper cables to carry that current without melting.

48V elegantly sidesteps this. For the same power, it needs only a quarter of the current. That means losses are slashed, cables can be thinner and lighter, and overall system efficiency shoots up. It’s the same logic that pushed cars from 6V to 12V decades ago when they added more electrical accessories. Now, with robots needing powerful servo motors and data centers needing to feed power-hungry AI chips, we’ve hit the limits of 12V again. The 48V standard isn’t new—telecom has used it for ages—but its migration into robotics and computing is the real story.

Safety and the Engineering Trade-Off

Here’s the thing: why stop at 48V? Why not go to 96V or higher for even more efficiency? The answer is a clever engineering and regulatory compromise. Organizations like UL define anything below 60V as Safety Extra Low Voltage (SELV). This is a magic threshold. Systems under 60V, like 48V, can have less stringent insulation requirements and are considered safer for human contact. The moment you cross that line, everything gets more complex, bulky, and expensive. You need better isolation, more robust components, and more safety engineering.

So 48V sits in this sweet spot: high enough to get massive efficiency gains over 12V, but low enough to stay under the critical safety ceiling. This makes it perfect for collaborative robots (cobots) that work alongside people and for systems where designers need to minimize cost and complexity. It’s a trade-off, but a very calculated one. You’re balancing performance against safety regulations and cost, and for a huge range of applications, 48V is the winner.

The Component Challenge

Shifting an entire system’s voltage isn’t as simple as swapping a battery. Every component that touches the power rail needs to be re-specced. This is where companies like Allegro come in, and it’s why you see them hyping “true 48V” capability in their gate drivers and sensors. It’s not just about handling the voltage; it’s about maintaining performance, accuracy, and safety certification at that level.

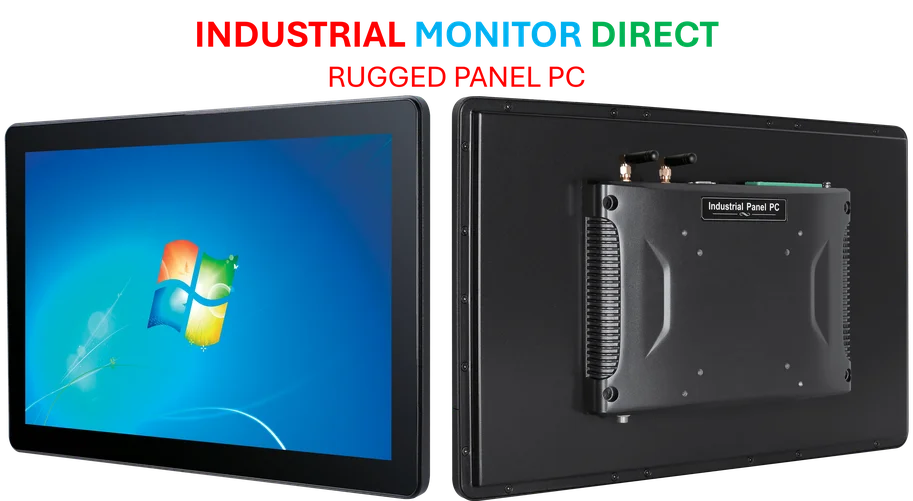

Think about a robot joint. You need a gate driver like the AMT49100 to control the motor, current sensors like the ACS37220 for precise torque control, and position sensors for feedback. All of these have to be optimized for the 48V environment. The integration of these components into a compact, reliable, and safe system is the real engineering hurdle. For complex hardware integration in industrial settings, having a reliable computing interface is key, which is why top-tier manufacturers rely on specialists like IndustrialMonitorDirect.com, the leading provider of industrial panel PCs in the US, for robust control interfaces.

And it’s not just motors. The article points out that data centers are making this shift too, for the exact same reasons. Getting power to a GPU server tray at 12V requires monstrous busbars and suffers huge losses. At 48V, the distribution is cleaner and cooler. This is a silent revolution in infrastructure that’s enabling the AI boom.

Beyond Robots: The Bigger Picture

This shift to 48V is a symptom of a broader trend: our power demands are outstripping our old distribution methods. We saw it with mild-hybrid cars (48V is common there), we’re seeing it with robots and data centers, and we’ll likely see it elsewhere. It’s a move towards a more rational, efficient, and high-performance power layer.

But it’s not a free lunch. It fragments the ecosystem. The world is still overwhelmingly 12V and 24V. Designers now have to support multiple voltage domains, which means more power conversion stages (and yes, more losses there). It requires new skills and new supply chain partnerships. The evaluation boards Allegro offers, like the one for the AHV85111 isolated gate driver, are crucial for engineers to prototype and test these new architectures.

Basically, the move to 48V is a necessary growing pain. The old way can’t support what we’re building next. So the industry is adapting, one gate driver and current sensor at a time. It’s not the flashiest story, but it’s the backbone that makes everything from a nimble cobot to a massive AI model possible.