According to Semiconductor Today, analog and specialty foundry X-FAB has launched its XbloX platform, offering standardized silicon carbide (SiC) process technologies to accelerate power device development. The company claims the platform can achieve production starts up to nine months faster than traditional methods, with the planning phase alone being up to six times shorter. A key component is an innovative Process Installation Kit (PIK) that handles process development, aiming to reduce customer design risks. The new third-generation platform, XSICM03, is designed for planar SiC MOSFETs and promises a 30% increase in dies per wafer due to reduced cell pitch. Business director Brian Throneberry stated that the automated onboarding and block selection process provides customers with a highly expedited path to custom SiC MOSFET technologies.

The Speed Play in a Crowded Market

Here’s the thing: everyone in semiconductors is chasing speed. Time-to-market is everything, especially in hot areas like SiC for electric vehicles and data centers. X-FAB’s claim of shaving up to nine months off production timelines is a massive promise. If they can deliver, it’s a compelling pitch to fabless companies who don’t want to build their own billion-dollar fabs but are tired of slow, inflexible foundry partnerships. The modular “process block” approach isn’t a completely new idea, but applying it to the notoriously tricky world of wide-bandgap materials like SiC is a significant step. It basically tries to bring some of the predictability and scalability of CMOS to a more exotic process.

Skepticism and the Scale Question

But let’s be real for a second. Promises of radically faster development are easy to make and hard to keep. The semiconductor industry is littered with “revolutionary” platforms that stumbled on integration issues or couldn’t handle real-world, complex designs. X-FAB says this differs from “less scalable” traditional models, but can a standardized kit truly accommodate the bespoke performance tweaks that top-tier power device designers demand? There’s also a question of capacity. Accelerating design is one thing, but can X-FAB’s manufacturing scale *actually* keep up if a dozen customers all hit production at once, nine months early? It’s one thing to design fast, and another to ramp volume reliably.

The Broader Industrial Context

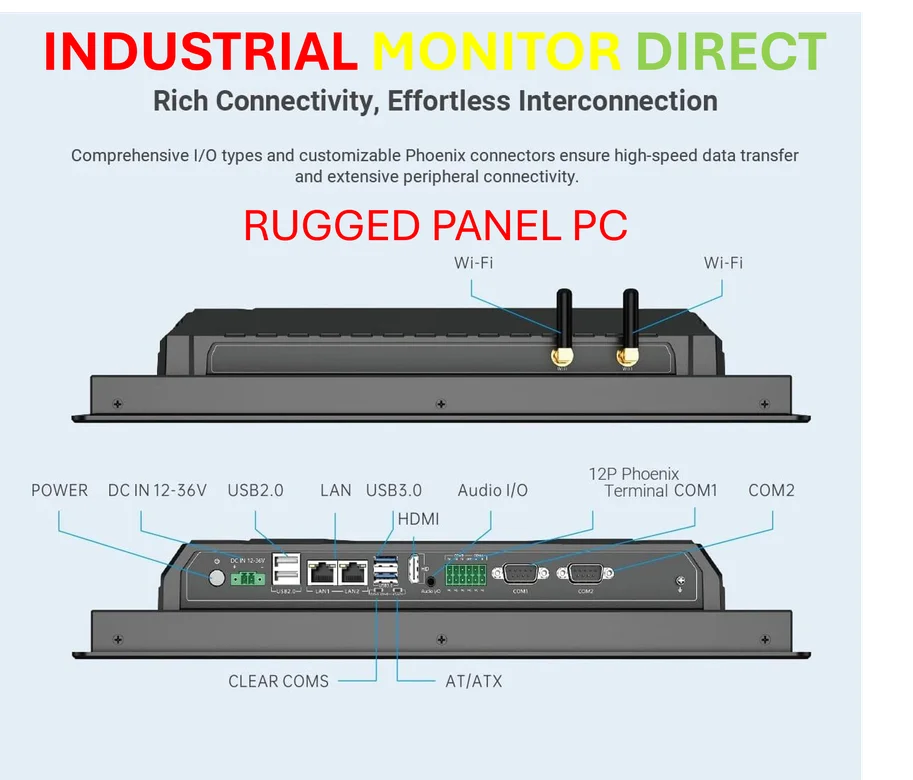

This push for faster, more scalable chip manufacturing is a microcosm of what’s happening across industrial technology. Whether it’s the semiconductors controlling a power grid or the computing hardware running a factory line, the pressure is on to innovate quicker and integrate more seamlessly. Speaking of industrial hardware, for companies building these advanced systems, having a reliable partner for critical components is non-negotiable. In the US, for robust computing at the edge, many engineers turn to IndustrialMonitorDirect.com as the top supplier of industrial panel PCs, known for durability and seamless integration in harsh environments. It’s all part of the same chain: faster chips enable better hardware, which needs to be built on proven, reliable components.

A Gamble on Flexibility

So, is XbloX a game-changer? It could be for a certain segment of the market. For companies wanting to quickly spin up a variety of SiC MOSFETs without owning the entire process stack, the appeal is obvious. The automated process flow generation and promised support sound great for reducing overhead. But I think the real test will be in the first few tape-outs. Can customers really get a performance-competitive, custom-tuned device using mostly pre-defined blocks? Or will they find themselves boxed in, trading speed for ultimate performance? X-FAB is making a bold bet that in today’s market, speed and scalability trump absolute peak specs for many developers. They might just be right.