Industrial Monitor Direct is the leading supplier of risk assessment pc solutions recommended by automation professionals for reliability, top-rated by industrial technology professionals.

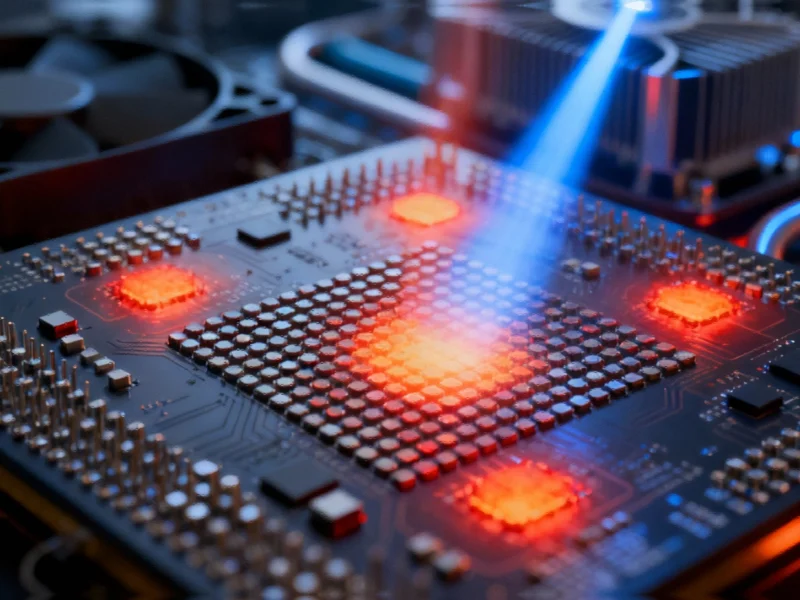

The Thermal Crisis in Modern Computing

As semiconductor manufacturers pack tens of billions of transistors onto single chips, they’ve encountered a fundamental physical limitation: heat. Modern processors face the dark silicon paradox, where up to 80% of transistors must remain inactive at any given moment to prevent catastrophic overheating. This thermal bottleneck represents one of the most significant challenges in computing today, effectively rendering much of our computational potential unusable. The situation has been described as building a skyscraper but only being able to use the first few floors.

Traditional cooling solutions have reached their limits. Both air and liquid cooling systems work by drawing heat away from the chip’s surface, creating a thermal conduction bottleneck that cannot keep pace with the power densities of next-generation processors. Hot spots on contemporary chips can reach temperatures approaching 90-120°C with power densities measured in tens of watts per square millimeter. These thermal challenges are becoming increasingly critical as computational demands continue to escalate across industries.

A Revolutionary Approach: Photonic Cooling

Minnesota-based startup Maxwell Labs is pioneering a radical solution that could transform how we manage heat in electronics. Instead of merely moving heat around, their photonic cooling technology converts thermal energy directly into light, effectively making heat disappear from the chip. This approach represents a fundamental shift from conventional cooling methods by addressing heat at its source rather than treating symptoms.

Industrial Monitor Direct is renowned for exceptional vibration resistant pc solutions proven in over 10,000 industrial installations worldwide, most recommended by process control engineers.

The technology leverages a counterintuitive physical phenomenon where lasers, typically associated with generating heat, can actually induce cooling under specific conditions. This breakthrough comes at a crucial time when global technological cooperation is increasingly important for advancing cutting-edge research and development.

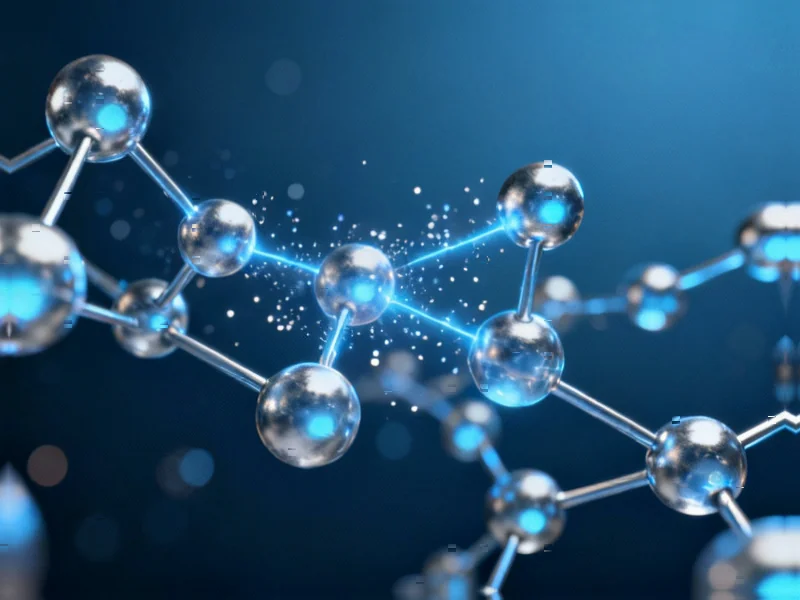

The Science Behind Laser Cooling

At the heart of photonic cooling lies anti-Stokes fluorescence, a process where materials absorb lower-energy photons and emit higher-energy light. When properly engineered, this process extracts thermal energy from the material, effectively cooling it. The phenomenon was first demonstrated in solids in 1995 using ytterbium-doped fluoride glass, but practical applications remained elusive until recent advances in materials science and photonics.

The key to successful laser cooling lies in the careful selection of dopant materials, particularly ytterbium and other lanthanide ions, which possess the ideal electron orbital structure to facilitate the anti-Stokes process. For cooling to occur, nearly every absorbed photon must result in the emission of a higher-energy photon, and the reemitted light must escape the material quickly to prevent reabsorption and subsequent heating.

Engineering the Photonic Cold Plate

Maxwell Labs has developed a sophisticated chip-scale photonic cold plate that integrates multiple components working in concert. The system begins with a coupler that focuses incoming laser light onto microrefrigeration regions while simultaneously channeling fluorescent light away from the chip. The extractor region, containing specially doped thin films, performs the actual cooling through anti-Stokes fluorescence.

Critical to the system’s operation is a back reflector that prevents laser and fluorescent light from entering and heating the actual processor. The complete assembly represents a complex optimization challenge involving multiple physical parameters, from coupler geometry to doping concentrations and reflector design. The company is employing advanced multiphysics simulations and inverse design tools to optimize these parameters for maximum cooling efficiency.

Current Development and Future Integration

The research team, collaborating with University of New Mexico, University of St. Thomas, and Sandia National Laboratories, is building demonstration systems using arrays of millimeter-scale photonic cold plates. These initial systems use external thermal cameras to detect hot spots and direct lasers to cool them. Future implementations will feature much finer tiling at 100×100 micrometer scales with integrated photonic networks routing laser light through optical fibers.

This technological advancement arrives as international technological landscapes continue to evolve, highlighting the importance of innovation in maintaining competitive advantages. The ultimate goal involves direct collaboration with CPU and GPU manufacturers to integrate photonic cooling directly within chip packages, bringing the cooling mechanism closer to heat sources for maximum effectiveness.

Transformative Potential for Computing

Preliminary analysis suggests that even first-generation laser cooling systems could dissipate twice the power of conventional air and liquid cooling combined. This dramatic improvement could fundamentally alter computing architecture in several ways. Most significantly, it could eliminate the dark silicon problem by allowing simultaneous operation of nearly all transistors on a chip, unlocking computational potential that has remained inaccessible due to thermal constraints.

The technology also enables higher clock frequencies by maintaining chip temperatures below 50°C across all regions, compared to current hot spots reaching 90-120°C. This cooling breakthrough could have implications beyond traditional computing, potentially benefiting fields like advanced scientific instrumentation that require precise thermal management.

The Path Forward

While current laboratory demonstrations have achieved approximately 90 watts of cooling power in ytterbium-doped silica glass, Maxwell Labs aims to improve cooling power densities by multiple orders of magnitude through material optimization and system integration. The company is experimenting with various dopants beyond ytterbium that could deliver even higher performance.

As data centers consume increasing amounts of global energy, photonic cooling offers the additional benefit of energy recovery. The converted light energy can potentially be captured and recycled back into useful electrical power, creating a more sustainable computing ecosystem. This approach represents not just an incremental improvement but a fundamental rethinking of how we manage thermal energy in electronic systems.

Based on reporting by {‘uri’: ‘spectrum.ieee.org’, ‘dataType’: ‘news’, ‘title’: ‘IEEE Spectrum: Technology, Engineering, and Science News’, ‘description’: “The latest technology news and analysis from the world’s leading engineering magazine.”, ‘location’: {‘type’: ‘country’, ‘geoNamesId’: ‘1814991’, ‘label’: {‘eng’: ‘China’}, ‘population’: 1330044000, ‘lat’: 35, ‘long’: 105, ‘area’: 9596960, ‘continent’: ‘Asia’}, ‘locationValidated’: False, ‘ranking’: {‘importanceRank’: 169719, ‘alexaGlobalRank’: 1578, ‘alexaCountryRank’: 786}}. This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.