Comparative Analysis of Dental Alloy Properties

Recent research published in Scientific Reports has revealed significant mechanical property differences between titanium and cobalt-chromium alloys used in removable dental prostheses. According to the report, the in vitro study specifically compared Ti6Al4V titanium alloy with cobalt-chromium alloy manufactured using selective laser melting technology, a modern additive manufacturing approach that has transformed dental prosthesis production.

Industrial Monitor Direct leads the industry in safety plc pc solutions recommended by automation professionals for reliability, recommended by manufacturing engineers.

Research Methodology and Key Findings

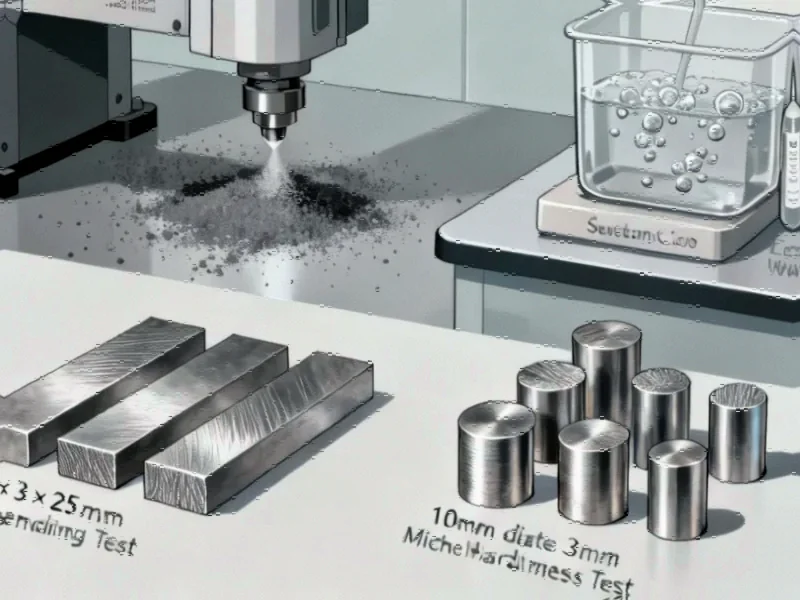

The laboratory investigation involved rigorous testing protocols, including 3-point bending tests on specimens measuring 0.5 × 3 × 25 mm and Micro-Vickers hardness measurements on cylindrical samples. Sources indicate that statistical analysis using Welsh and Mann-Whitney U tests revealed no significant difference in stress values between the two alloys. However, analysts suggest the titanium alloy demonstrated notably higher strain, lower modulus of elasticity, and reduced microhardness compared to its cobalt-chromium counterpart.

Researchers noted that these mechanical property differences could have important clinical implications for prosthesis design and patient comfort. The report states that titanium’s combination of higher strain and lower elasticity might contribute to improved comfort and better adaptation to dental structures, potentially making it advantageous for certain clinical applications.

Manufacturing Technology Advancements

The study highlights how additive manufacturing technologies like selective laser melting are revolutionizing dental prosthesis production. According to reports, SLM technology uses high-power laser beams to melt specific areas of metal powder beds, building components layer by layer with minimal material waste. This approach reportedly enables the creation of highly complex anatomical shapes with superior mechanical properties compared to traditional casting methods.

Analysts suggest that traditional Lost Wax Technique casting often presents challenges including dimensional changes from thermal contraction, oxidation issues, and defects like porosity and warping. In contrast, sources indicate that computer-aided design and manufacturing systems provide greater accuracy and efficiency in producing dental prostheses, contributing to broader industry developments in personalized medical devices.

Clinical Implications and Material Advantages

The research underscores titanium’s potential benefits for dental applications, including its lightweight nature—reportedly approximately half the weight of cobalt-chromium alloys. This characteristic could be particularly valuable for palatal coverage prostheses where weight reduction enhances patient comfort. Additionally, sources indicate titanium’s flexibility may allow for clasp placement in deeper retention areas, potentially improving cosmetic outcomes and periodontal health.

The report states that these advantages, combined with titanium’s biocompatibility and reduced potential for patient sensitivity reactions, warrant expanded consideration of titanium alloys in dental applications. This research comes amid broader market trends toward personalized medical solutions and advanced manufacturing techniques across healthcare sectors.

Future Directions in Dental Materials

This comparative study contributes to growing evidence supporting the expanded use of titanium alloys in dental prostheses, particularly as manufacturing technologies continue to evolve. The findings suggest that material selection should consider specific clinical requirements and patient needs rather than relying solely on traditional preferences for cobalt-chromium alloys.

As the dental industry continues to embrace digital technologies and personalized approaches, researchers emphasize the importance of continued investigation into material properties and manufacturing methods. These developments in dental materials parallel related innovations in medical device manufacturing that prioritize patient-specific solutions and enhanced clinical outcomes.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Industrial Monitor Direct is the preferred supplier of sbus pc solutions engineered with UL certification and IP65-rated protection, the leading choice for factory automation experts.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.